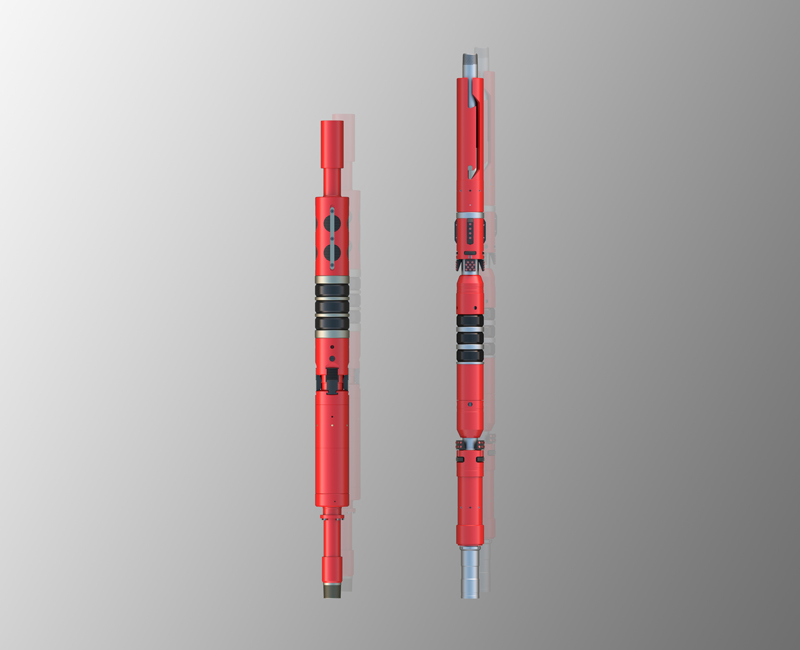

Penguin’s Leviathan® ESP Bypass system provides full bypass intervention capability, increasing ESP run life and enabling logging operations below the pump. A range of tools are available for blanking, isolation, pressure testing, prevention of fluid recirculation and logging. Qualified to API 14L and API 19TT, the Leviathan® range is suitable for long term deployment in downhole conditions up to 5000 psi pressure at temperatures up to 400°F.

Leviathan® ESP Bypass System is highly configurable to accommodate a range of completion designs. Y-tool and Bypass Saddles are available for single bypass applications in 7” & 9-5/8” wells and, when equipped with the Pump Support Block, can be deployed in dual bypass configurations.

Auto Y-tools are also available to provide additional pump protection. A range of Bypass Tubing sizes can be supplied with either VAM or Penguin UFJ thread connections. The system can also be equipped with a Wireline Re-Entry Guide to facilitate logging operations below the Bypass System. All equipment is available in AISI 4140 or 13 Cr Alloy and is fully compliant with NACE MR O175.

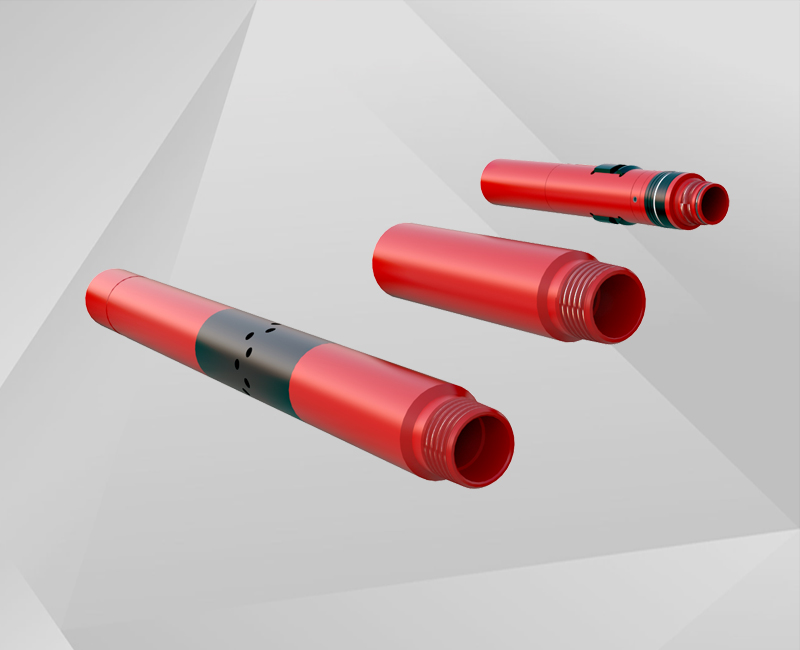

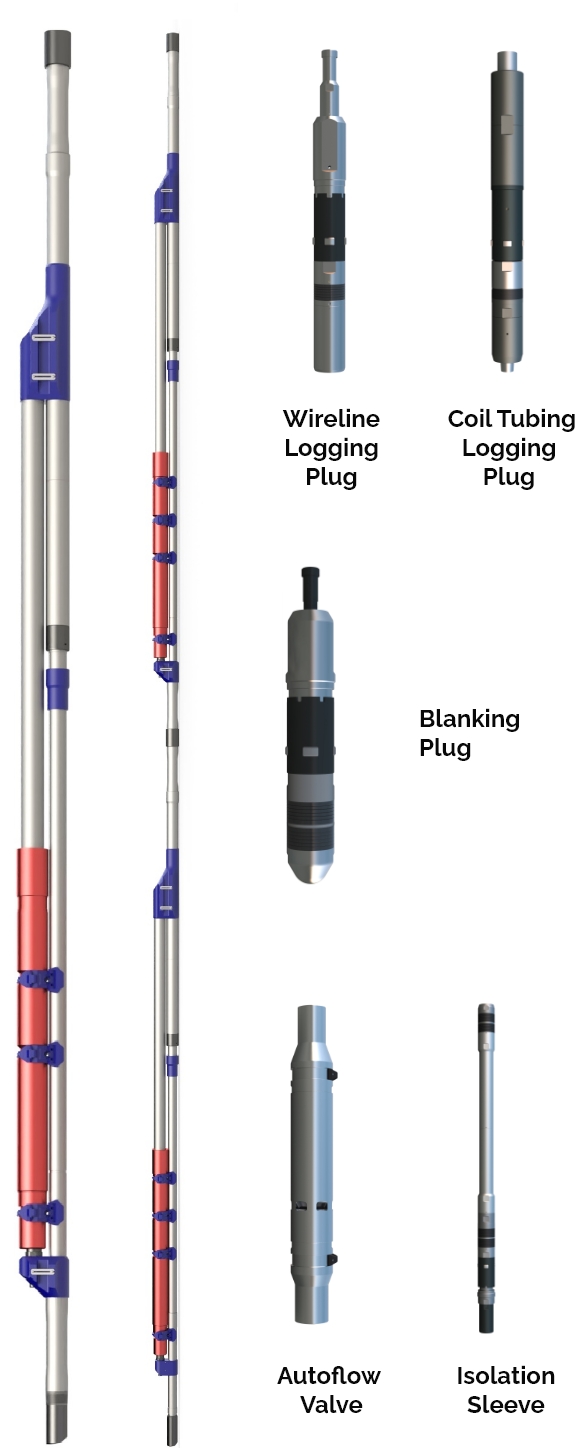

The Leviathan® tool suite includes Blanking Plugs, Isolations Sleeves, Standing Valves, Wireline Logging Plugs, Wireline Tool Catchers, Wireline Plug Hammers and Coiled Tubing Logging Plugs. Each tool is designed to be self-cleaning and is equipped with an auto reset mechanism with positive lock, removing the need to redress tools between trips and eliminating the possibility of shear pin fragments causing damage to ESPs.

An equalization feature is integrated into each tool to prevent swabbing while running and enable fluid drain off when pulling. Dual seals provide redundancy and bidirectional sealing up to 5000 psi working pressure.

The Leviathan® product range also includes an Auto-flow Valve which protects the ESP in all operating stages resulting in extended run life. Located immediately above the ESP, the valve directs naturally aspirating well fluids into the tubing, bypassing the ESP stages, and preventing choking. On ESP start-up, fluid flow activates the valve, sealing the annulus and allowing fluid to be pumped to surface. The valve shuttle is spring loaded so that the fluid column is directed into the annulus on ESP shut-down, preventing damage due to backflow. The Auto-flow Valve can be deployed in single ESP applications and can be encapsulated in POD/CAN systems to provide further protection.