Sucker rod pumping is one of the oldest and reliable mode of artificial lift globally used for producing oil. Roughly two thirds of artificially lifted wells around the globe are installed with sucker rod pumps. It is the most economical and mechanically simple artificial lift method with relatively easy availability of required parts and skilled manpower. Rod pump system is capable of producing a well down to very low pressures to maximise the oil production and used in applications involving slim hole, multiple completions, viscous and high temperature fluid production.

Except for certain specific applications, majority of sucker rod pumping systems operating all over the world are in conformity with American Petroleum Institute (API) specifications 11AX. API specifications 11AX covers the technical parameters and requirements of sub surface sucker rod pumps and parts and standardizes the pumps and parts for pump bore sizes, dimensional requirements, parts interchangeability, base material requirements, plating/coating properties etc.

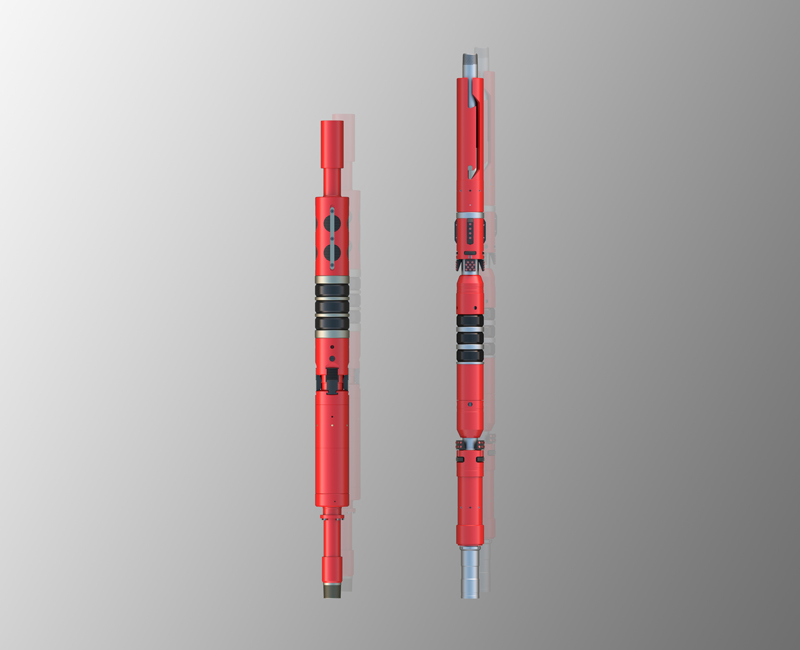

Penguin manufacturers sub-surface sucker rod pumps and pump parts conforming to requirements of API 11AX under its brand name Prolift™. Prolift range of Sub-surface sucker rod pumps are manufactured using advanced technology and state of the art machinery, testing & inspection devices and gauges. The pumps offered are in the range of 1-1/16” to 3-3/4” bore sizes as per API pump designations as well as oversized tubing pumps (OSTP) as per customer requirements.

Penguin is also capable of designing and manufacturing non-API pumps for specific applications with exotic metallurgies incorporating customer specified parameters and configurations. Hard lined or insert lined valve cages are also available upon request.

Penguin also design, manufacture and supply various SRP accessories such as Insert Pump Anchors, On-Off tools, Tubing Anchors etc.

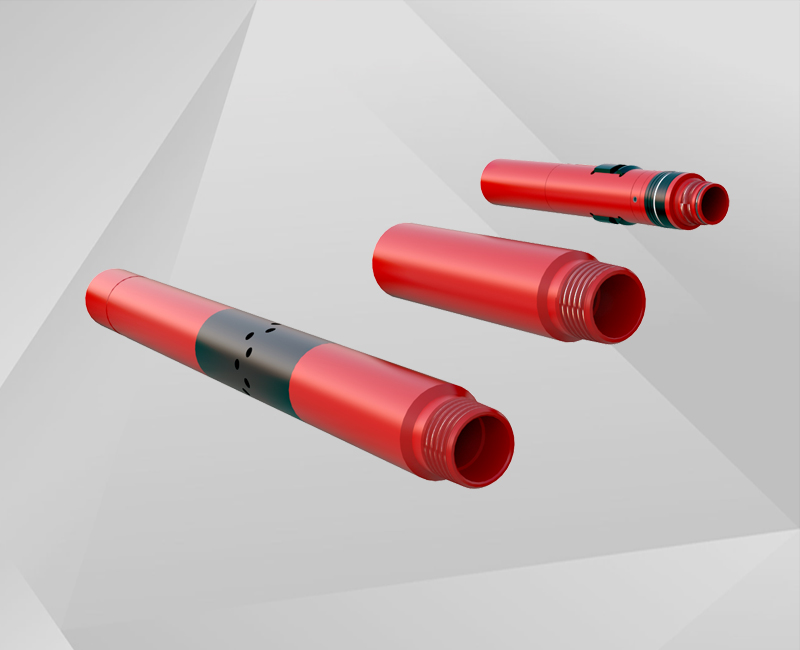

Sucker Rod and Polished Rod Couplings – API 11B

Penguin also manufactures Sucker rod couplings, Sub couplings and Polished rod couplings in varying sizes of 5/8, 3/4, 7/8, 1-1/8 inches dia. meeting or exceeding the requirements of API Spec 11B. Couplings and Sub couplings are available in alloy steel AISI 4130/8630 grades and are effectively heat treated to meet or exceed mechanical properties as specified in API 11B. All couplings are precision CNC machined to maintain the perpendicularity of coupling face to coupling axis to ensure proper friction sealing while making up with sucker rods.